Safe Sample Mining

DKT İnşaat San. operates in the fields of Mine Management, Crushing-Screening-Washing Facility Management, Explosive Excavation and Earthworks. and Tic. A.Ş. reflects the significant experience it has gained in its field thanks to its years of work. DKT, which has been involved in Turkey's leading construction and mining projects since the day it was founded, achieved a first in the sector by increasing the 20 million tons of aggregate it produced in 2017 to over 30 million tons in 2018, and continuously increased its annual production tonnages in the following years. DKT still continues quarry operation, aggregate production, explosive excavation and earthworks in the Highway-Tunnel-Railway construction projects in Azerbaijan-Karabakh, which it started in 2021. 1,500,000 per month in the quarry operations of our company in the project in question. It delivers tons of aggregate and also carries out 1,500,000.m3 monthly blast-excavation and filling work.

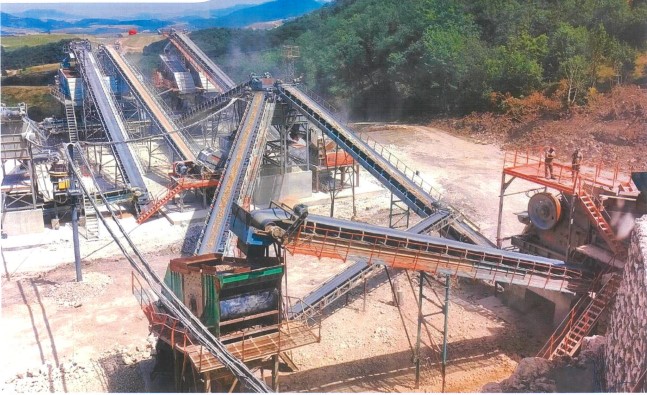

In 2017-2020, it broke an unprecedented record in its sector by operating a total of 20 Crushing and Screening Facilities and 2 Press Washing Facilities, the smallest of which had a capacity of 400 Ton/h.

The importance DKT attaches to engineering science directly affects its success. The construction sites are operated under the control and management of the site chief engineers and field engineers working at each site. DKT aims to take the sector to a further point in both engineering and technology with its R&D studies in the field of crusher, screening and part designs, which continue in close contact with different facility manufacturers. With the help of more than 20 expert engineers currently working in different positions, it manages the Crushing and Screening Facility and Quarry Operation with the aim of producing the most efficient and gradable aggregate.

"DKT, which acts with the perspective of "Safe Model Mining" and is fully aware that its work is in the hazardous work class, employs 15 full-time occupational safety experts, including class 2A and class 13C. In addition to daily occupational safety training, all DKT field employees also receive certificates related to the field of work they work in. In addition, closure and modern dust reduction systems in accordance with the legislation are used in all DKT facilities.

DKT, which attaches great importance not only to production but also to occupational health and safety and administrative issues, with the experience of constantly working with leading companies and organizations in its sector in large projects, assumes a leadership role in its field of activity with more than 800 employees and with a constantly growing momentum. is undertaking new projects.

OUR VALUES

Being aware that our work is in the hazardous work class, we follow our SAFE MINING principles at every moment of our work.

We always strive for PERFECTION with our detail-oriented approach with engineering rigor.

With our human, environment and employee-oriented approach, we always act respectfully not only to our business but also to our stakeholders and conduct EXAMPLE MINING.